Some interesting developments at the ol’ homebrewery. I purchased a canning machine from Oktober Design at Homebrew Con, and I finally had the time (and the beer) to take it for a test drive. Unfortunately for my dumb ass, I purchased my cans on sale from MoreBeer and they were 16.9oz cans instead of the 16oz I needed.

Some interesting developments at the ol’ homebrewery. I purchased a canning machine from Oktober Design at Homebrew Con, and I finally had the time (and the beer) to take it for a test drive. Unfortunately for my dumb ass, I purchased my cans on sale from MoreBeer and they were 16.9oz cans instead of the 16oz I needed.

Never one to be deterred by rules or “common sense” I pressed onward with my stupid, wrong-ass cans and canned up a brewer’s dozen (18) of the pale ale. And as with all my mistakes brilliant ideas, I decided to share my thoughts here.

First on the canning… holy shit, this is so much better than bottling I can’t even begin to describe it (he said before beginning to describe exactly it). There’s a little more of a learning curve as to when to stop filling the can vs. filling the bottle since you have the opaque vessel, but the cans that I seamed properly seemed (haaaa) to hold the carbonation as good or better than any beers I’ve bottled. Plus, aesthetically the cans – with a couple bare-bones stickers – are just sharp as hell.

In short, I absolutely love my canner and can’t wait to try with the actual, correct sized cans, so that all my seams aren’t janky af and prone to leaking.

Pale Ale Tasting Notes

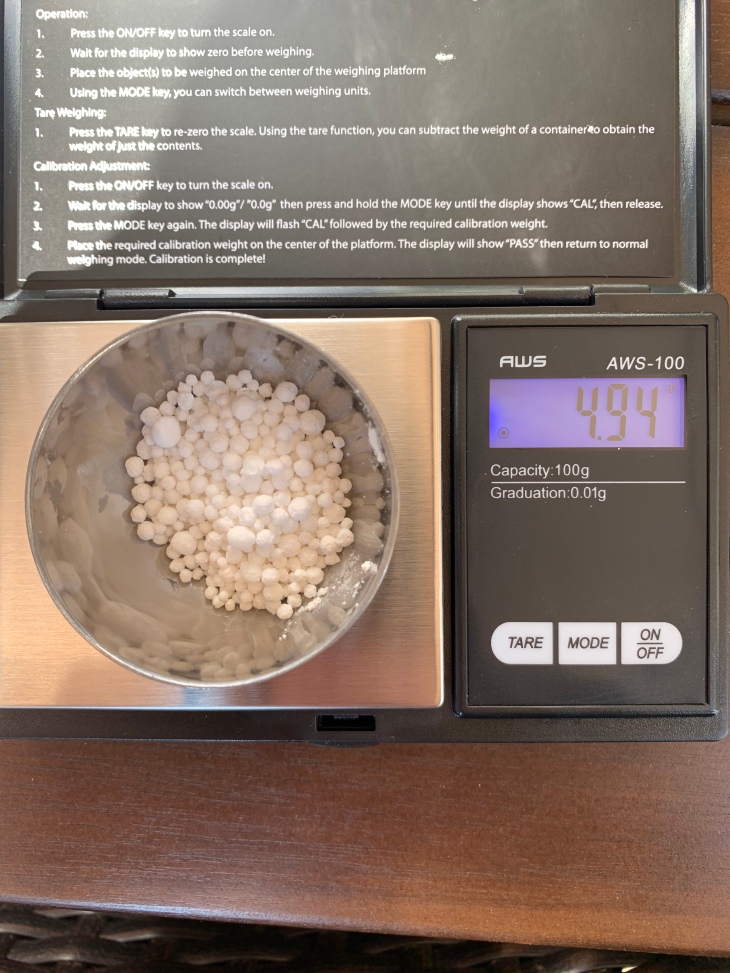

First, we haven’t reached the naming stage yet with this beer because there’s a handful of changes I want to make to this version. Among those changes, the primary one is that I’d like to rebrew this recipe without messing up the water adjustments. I’m anxious to see if I can get a similar flavor profile but with a drier finish that is more in line with a traditional American Pale Ale or West Coast IPA. Anyways, let’s get into it and I’ll pontificate as we go…

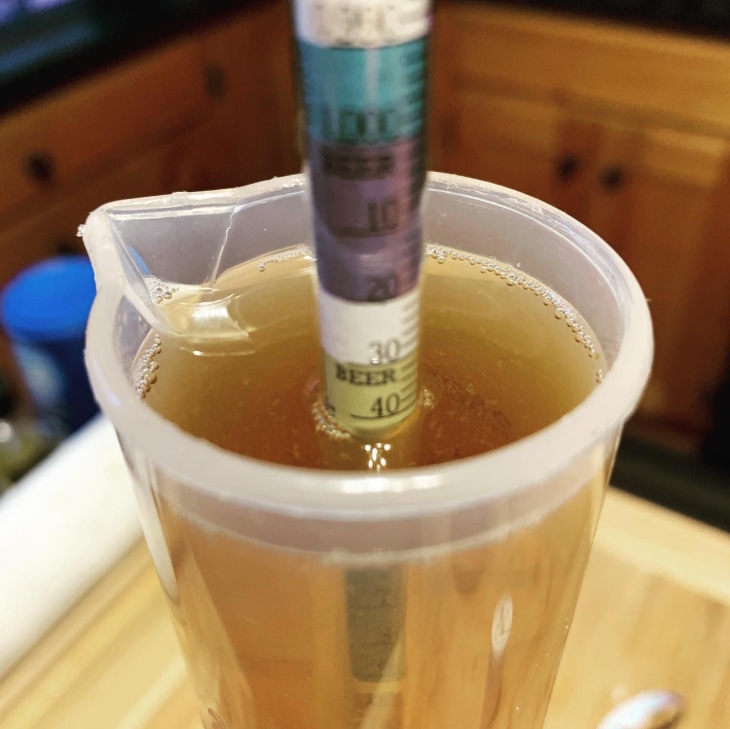

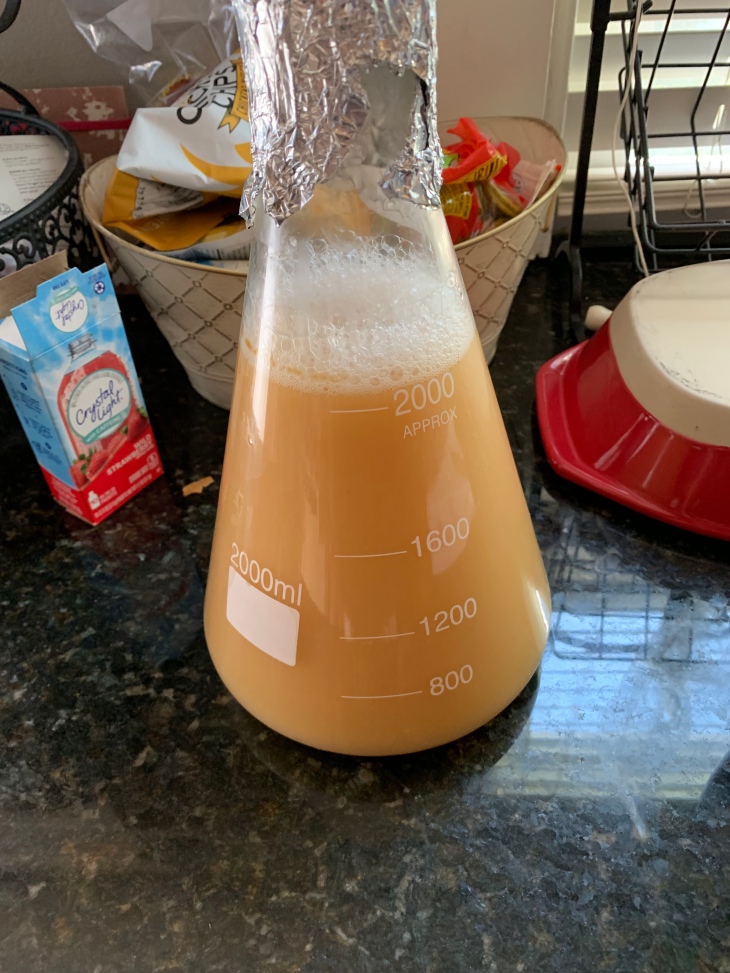

Appearance: Hazy, but not “New England” hazy. After fining with gelatin and cold conditioning I would have expected a good deal more clarity from this beer. I’m planning to write a whole post on my issues with achieving clarity, but suffice it to say I wish this was a little closer to sparkling (with some forgiveness for the ample dry-hopping). Color-wise, it’s right around the 6-8 SRM range, which is what I was aiming for… and now regret. It’s a tinge more orange than what I wanted. It’s not an ugly color (especially if I could eliminate the turbidity), but – and stick with me here – I’d like my pale ale to be a little paler.

Aroma: You every hit a baseball and know instantly it’s a homerun? Shoot a shot and know it’s nothing but net? So confident in your Jeopardy! so you actually form it as a question, even though you’re on your couch and the rules don’t apply? Man, that’s this aroma. On a scale of 1-10, it’s 107. Just big-ass tropical fruit, citrus, mango, pineapple, love, justice, liberty, and self-respect. Smelling this beer actually makes you a better person. Idado Gem, y’all, it’s legit.

Taste: I am… pleasantly surprised. This presents itself as big and juicy, but drinkable. It’s missing the bitterness you’d expect from an American Pale, and the body is too full, but taken on its own merits, I’m definitely drinkable. Huge bursts of fruit – mango, pineapple, citrus, orange – really dominate, but there’s also a little bready/nutty character from the malt that also comes through in the absence of the bitterness.

Mouthfeel: Medium to medium-full with a nice, white, rocky head. This comes across fuller and juicier than I had designed. The mouthfeel and body shifts the style of this beer from American Pale to New England Pale. This tastes and drinks like a Session NEIPA. Not the least bit cloying, but may just a little slick. I wish it was drier.

Overall: I set out to make a traditional American Pale with some funky new school hops and honestly, I failed at that. I think the combination of the clarity issues and the mistakes with water adjustment completely shifted what this beer became. It’s funny how small mistakes can take the beer into a completely new direction. That said, this beer is DELIGHTFUL. I think the seal on the cans is letting some of the carbonation out, but outside of a little flatness, this is a really good beer.

A brief story, I had a glass of this Pale Ale after work before heading out to dinner. The restaurant we went to had Trillium’s DDH A Street and Stellwagen’s Modulation #11 on tap, and I preferred drinking this damn homebrew to either one of those (good-to-very-good) commercial beers.

Final Thoughts: I talked a little bit in the Pale Ale brew day post about how I was kind of down on my brewing skills and the beers I’d been brewing. Man, this beer has spun my head a straight 180. With a little forgiveness for packaging defects and minor quibbles with process (and their results in the finish product) this would be a beer I’d pay $8 for at a nice gastropub and go “Oh yeah, I’ll fuck with this.” I can’t tell you how good that feels (he said after spending 900 words telling you exactly that).